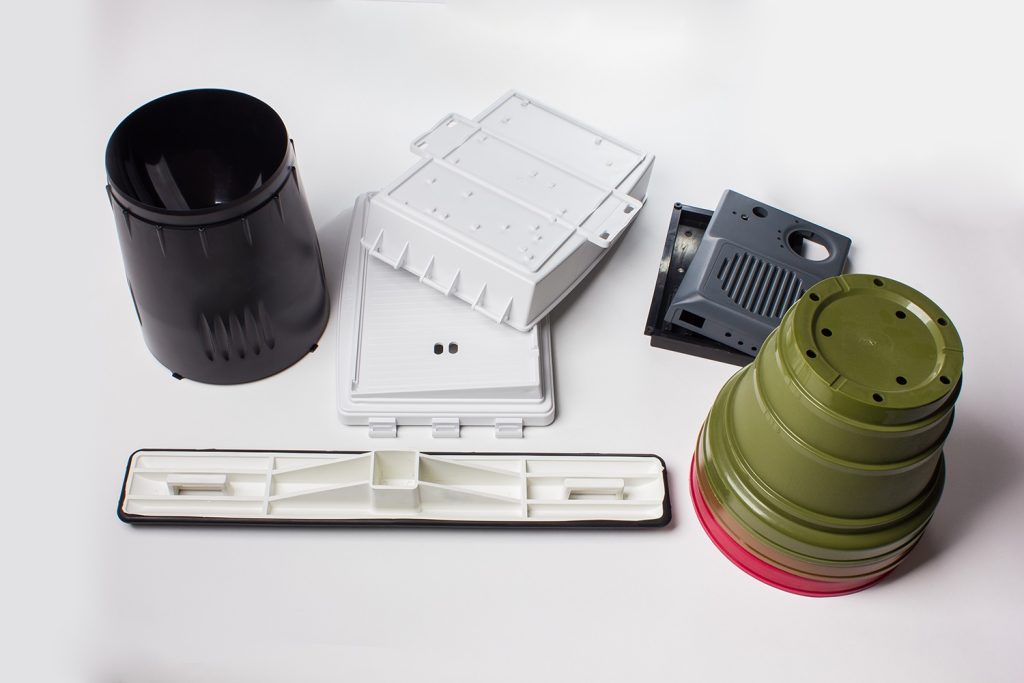

High-Quality Injection Molding to Meet Your Needs

Central Plastics is a precision custom injection molder. We have the right equipment to handle jobs that require press capacities ranging from 24 to 800 tons. Our machines can cater to your lightweight parts with larger cavitation molds, fulfilling your high production needs at a competitive price.

We offer advanced molding technologies such as:

- Overmolding

- Insert molding

- MICRO precision molding

- Class 100,000 clean room molding

- Plastic part assembly

- Medical device assembly

During production runs, our plant-wide process monitoring system observes press variables such as temperatures, pressures, and cycle times. These parameters are recorded and can be used for later production runs to ensure part consistency. We also utilize automated injection molding equipment that can ensure the same amount of material gets introduced to the mold each time.

We specialize in processing a variety of materials, including:

- Engineering grade resins

- Medical grade resins

- Food grade FDA approved resins

- Electrostatic resins

- Resins with glass fiber, stainless steel fibers, etc.

It’s our service that separates us.

After each production run, all molds are inspected, cleaned, and maintained in our fully equipped tooling room at no cost to our customers. Our 24-hour operations enable us to accommodate high-volume requirements and allow us to meet tight delivery schedules. Our molding department operates under ISO 9001, AS 9100, & ISO 13485 procedures, reflecting our commitment to quality and consistency. Our molding processes are subject to stringent external audits and must remain in compliance to retain certification.

Contact Central Plastics today to learn more about our expert plastic injection molding services.